Metal 3d Printing Technology: A Beginner’s Guide

What Is It?

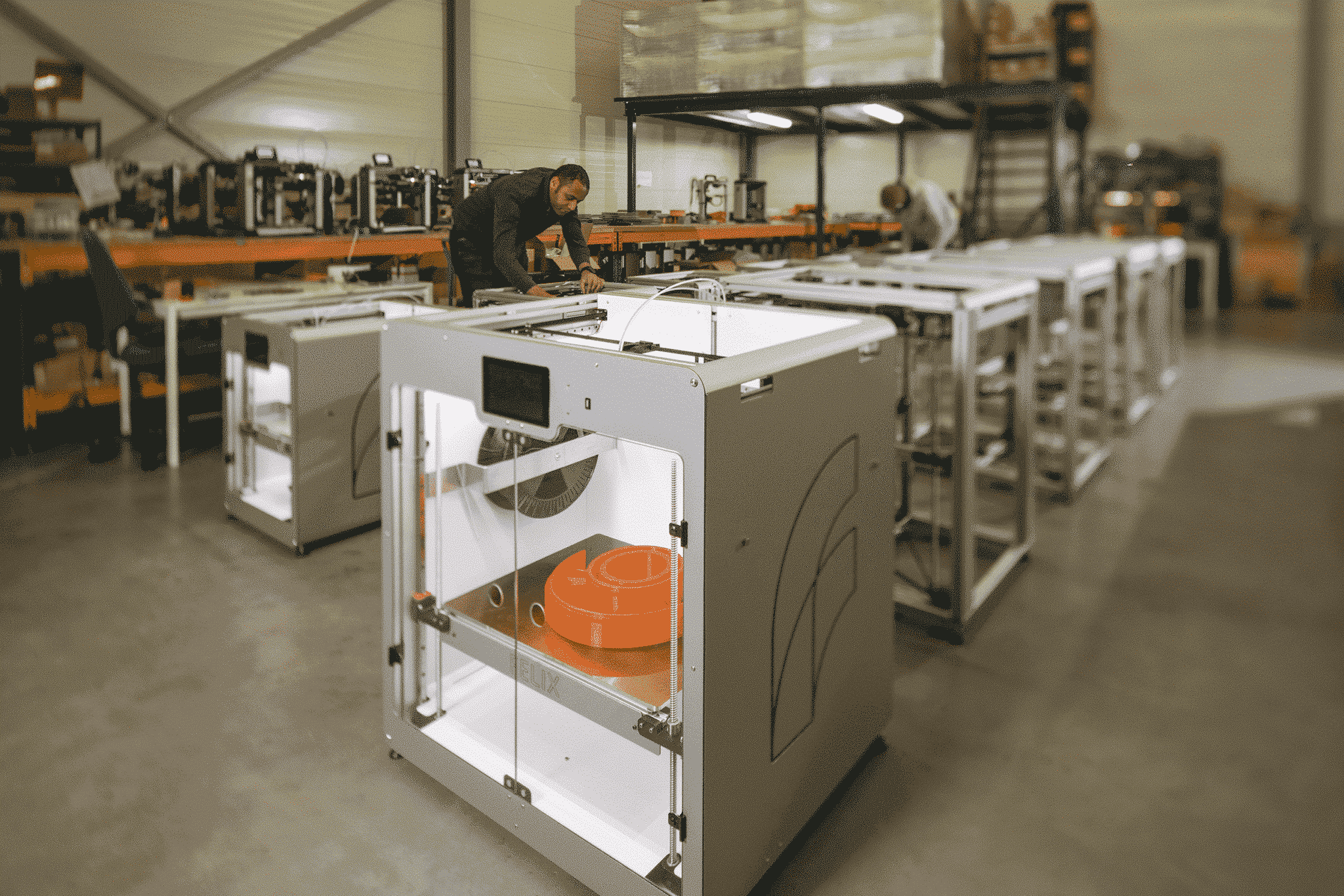

Metal 3D printing or metal 3d printing technology has grown dramatically in recent years due to rapid technological advancement. Many innovative startups and suppliers have recently proposed more affordable metal 3D printing processes, as well as an increasing number of compatible materials.

Metal 3D printing is crucial in many industry sectors. Sectors like aerospace, automotive, and medical use this technology. The reason?; it allows for the printing of complex metal parts at a lower cost than traditional manufacturing processes.

Metal 3D printers have recently seen significant advancements. Hybrid systems, metal deposition, recovery materials, and other cutting-edge projects have made the process more efficient.

The Materials

Among the most widely used material in metal 3D printing is aluminum. Its use is in alloy form. Aluminum is crucial because it is both robust and light. Its primary use is when weight reduction is critical, such as in the aerospace and automotive industries. Steel is also widely used, particularly in industrial applications. Steel has good mechanical properties and a smooth surface finish. As a result, it is the most commonly used metal in 3D printing.

For medical applications, there are metals such as gallium, cobalt-chrome, and titanium due to their good resistance to corrosion and biocompatibility.

The Application

Metal 3D printing is currently being used in industry to create tool components and finished products in industries such as aerospace and automotive. 3D printing or metal 3d printing technology can be used to create aircraft components or rocket engines, saving weight and money. Metal 3D printing can also be used in the medical field, such as implants for analysis, particularly in dentistry. Metal additive production can even design boat propellers in the marine industry.

You May Also Like

Standard Help Guide to on the Online Clothes Shopping

September 23, 2023

Know the specialty of chocolate bar singapore

September 23, 2023